Specialty printing LLC

Digital Prepress Designer

Specialty Printing is a leading manufacturer of sustainable labeling whose products can be found in retail and grocery stores, hospitals and medical facilities, restaurants, distribution centers, post offices, and more.

My primary role as Digital Prepress Designer was to support our Digital department, ensuring all artwork for jobs was optimized and properly prepared to print accurately on a variety of substrates. I worked directly with press operators to manage colors during first runs and to maintain precise color accuracy during repeat runs between presses.

Our Clients

Prepress & Color Management

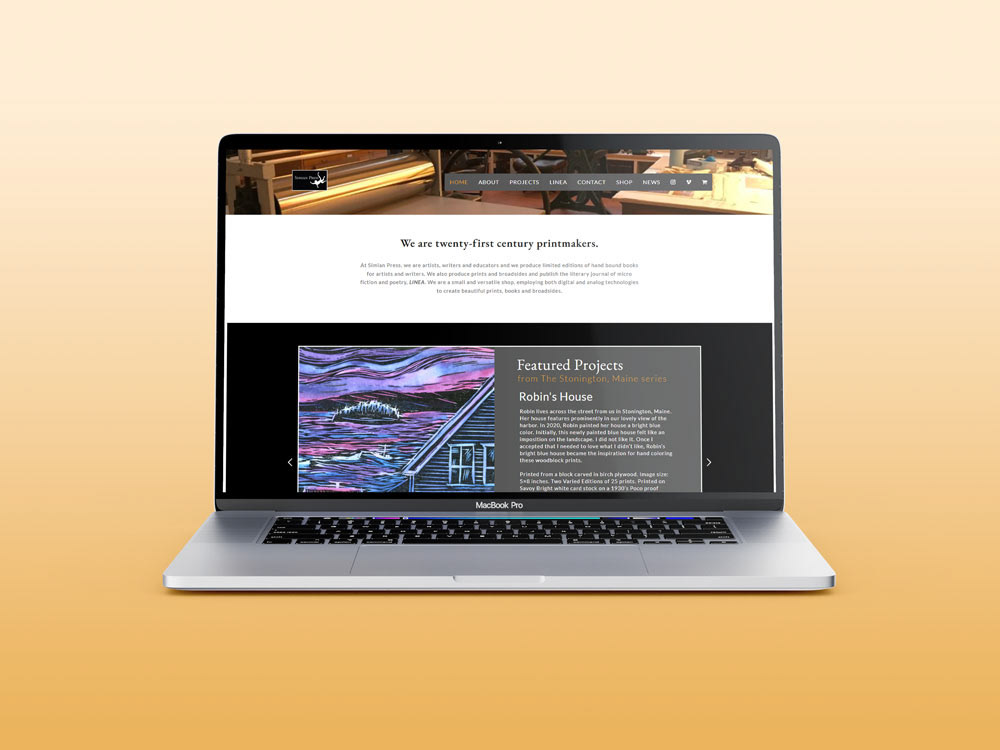

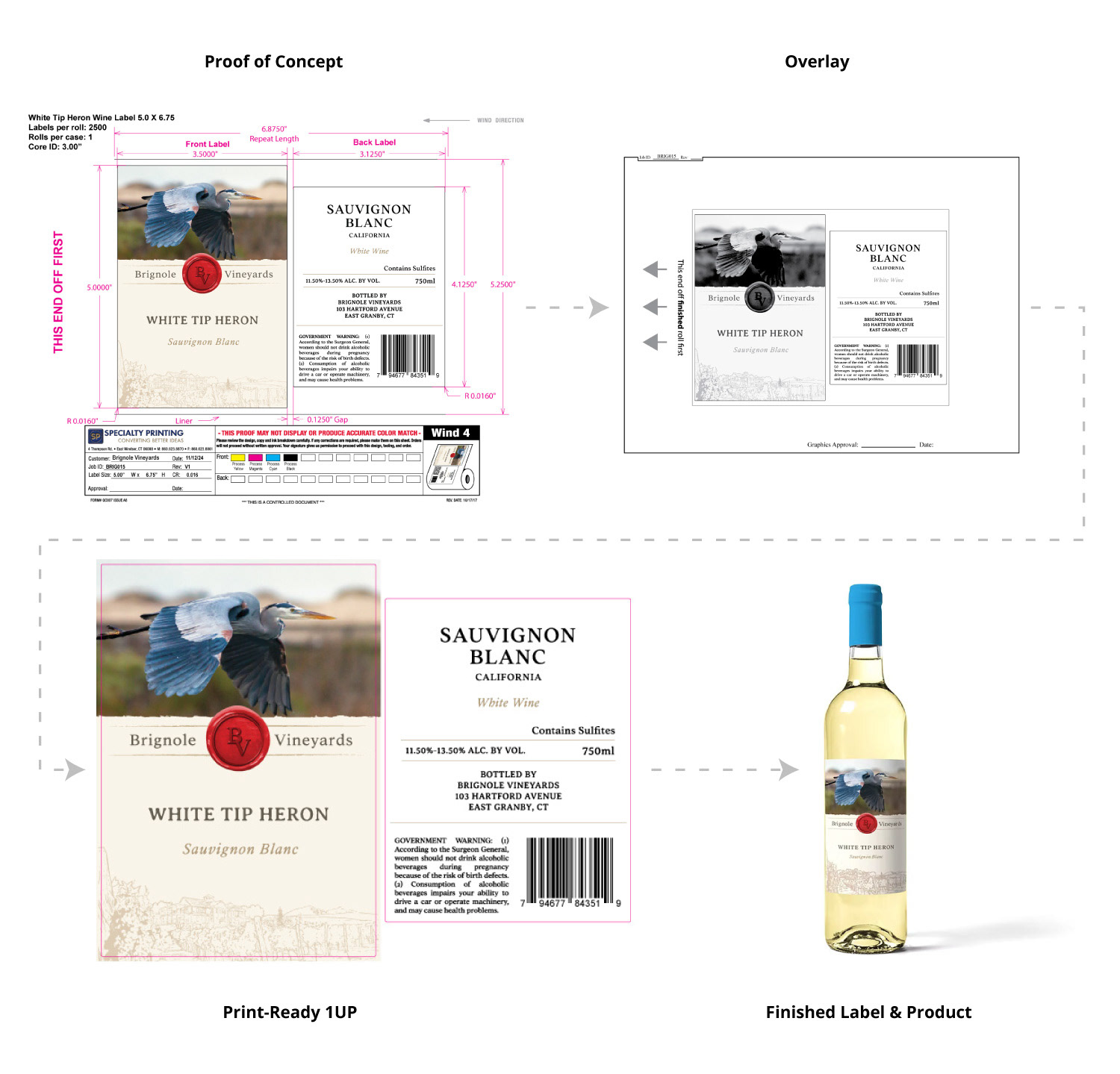

At Specialty I took files from the concept stage through the process to becoming a printed product. Working with regulatory and design teams to create artwork and to iterate on existing designs across food and beverage, medical, and pharmaceutical labels.

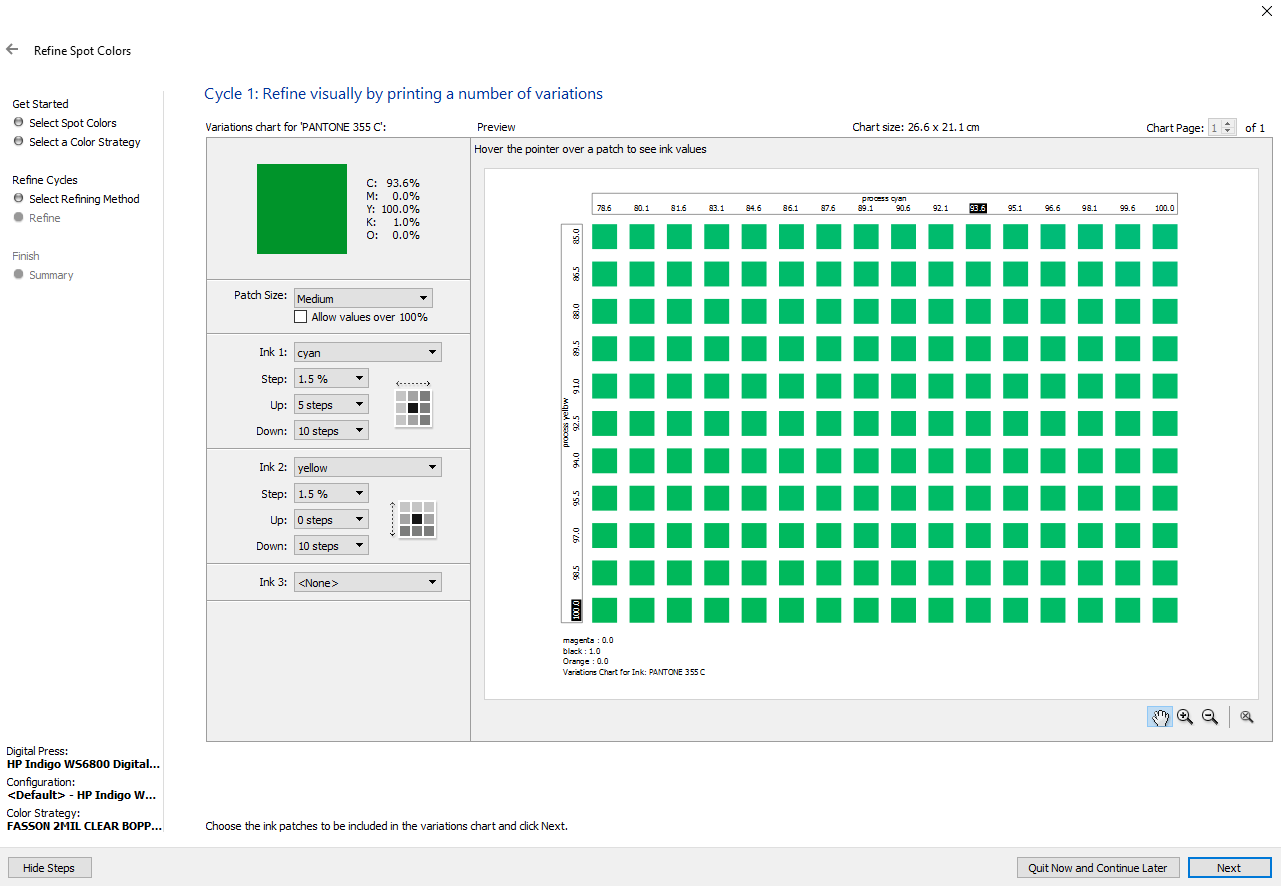

The process of getting artwork on to the process included creating artwork, speccing and proofing artwork and dielines, creating overlays, adjusting layouts to ensure accurate representation of artwork during printing. Once on press, I worked with operators to create custom profiles through use of color variation charts for individual spot colors, keeping spot colors at or below a Delta E reading determined by our corporate standards.

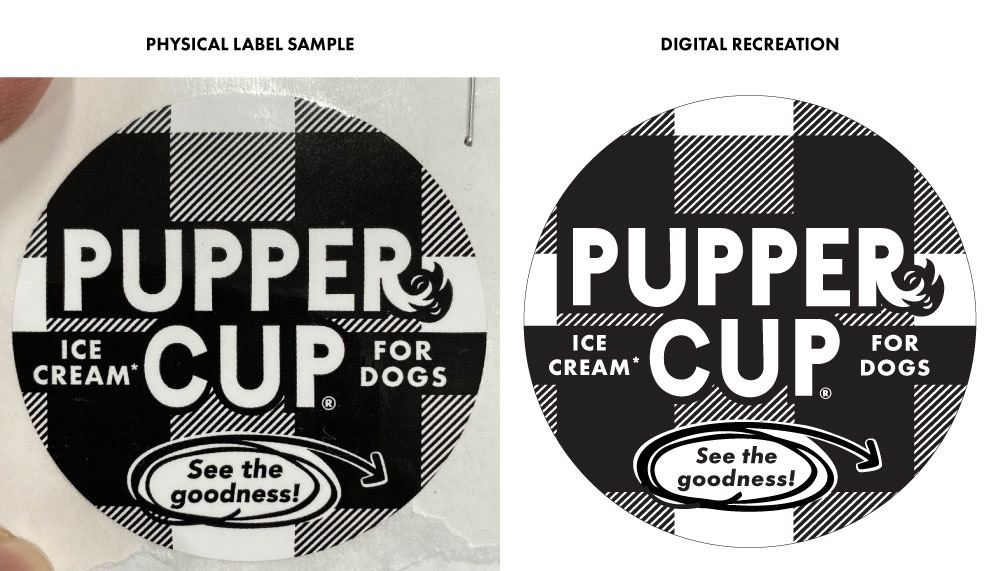

Label Rebuilds

During the process of acquiring new business, the sales team would bring in clients that did not have existing artwork. In these instances, labels would need to be rebuilt using a photo or physical sample of the existing item. Using Illustrator, Photoshop, a Pantone book, and a spectrodensitometer I diligently rebuilt labels for customers, striving to reproduce their items as closely as possible. These are examples of labels I rebuilt and in some cases worked with the customer to improve on previous designs.

Procedures for digital prepress

As the sole designer in charge of digital prepress, I took initiative to create procedures to guide team members to be able to perform some of my duties. This enabled my team to be more flexible and reduce scheduling conflicts that can result in press downtime.